Products

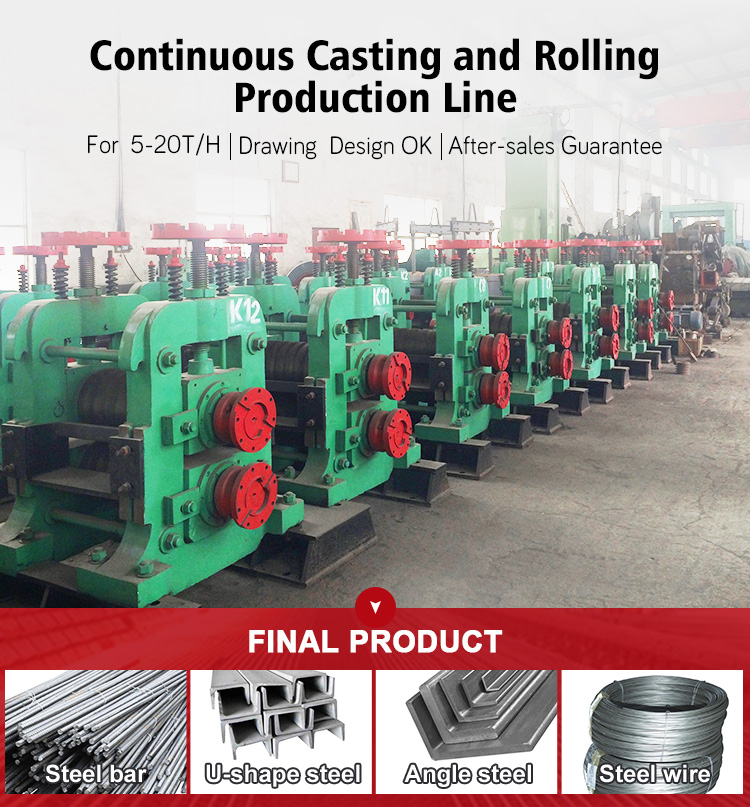

Continuous Casting and Rolling Production Line for Wire rod, Steel rebar, Section bar, flat bars

Description of production line

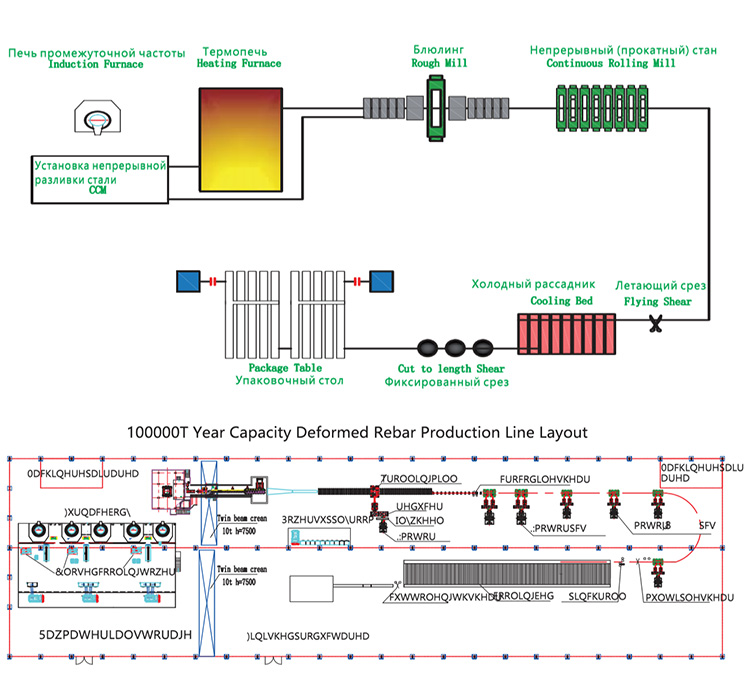

Continuous casting and rolling Production Line including Induction Furnace, CCM Machine, Heating Furnace, Rough Mill, Continuous Rolling Mill, Flying Shear, Cooling Bed, Cut To Length Shear, Packing Table etc.

Features of Continuous rolling mill

* Save energy consumption by using continuous casting blanks heat energy.

* Improve the metal forming and save the metal consumption.

* Simplify production process , reduce plant area and transportation cost, save infrastructure investment and production costs.

* Greatly shorten the production cycle

* Improve the quality of the products

* The raw material is steel scrap or billet (40-120mm).

*The production capacity is suitable for 5~20t/h, and the diameter of the steel bar of the finishing product: 6.5-32mm

Technical specifications table

| Annual capacity(T) | Capacity(TPH) | Working hour/year | FurnaceCapacity(T) | Continuous casting | Continuous Rolling | Area(m) | Power(MW) | Remarks | |||

| Model | Section(mm) | Rough | intermediate | Finishing | |||||||

| 7000 | 3 | 2400 | N/A | R2.5 | 40×40 | FF250x2 | Ff220x2 | FF220x2 | 40×10 | 0.6 | 8~32mm |

| 10000 | 4 | 2400 | 1.5Tx3 | R2.5 | 50×50 | FF280x3 | FF250x2 | Ff220x2 | 80×15 | 4.5 | 8~32mm |

| 12000 | 5 | 2400 | 2Tx3 | R2.5 | 60×60 | FF280x3 | FF250x2 | FF250x2 | 120×20 | 5 | 8~32mm |

| 20000 | 8 | 2400 | 3Tx3 | R2.5 | 70×70 | FF350x3 | FF280x2 | FF250x2 | 120×20 | 8.5 | 8~32mm |

| 40000 | 10 | 3600 | 3Tx4 | R3.5 | 90×90 | FF380x3 | FF300x2 | FF280x2 | 150×20 | 9.5 | 8~32mm |

| 50000 | 15 | 3600 | 5Tx3 | R5.5 | 120×120 | FF450x3 | FF350x2 | FF280x2 | 180×20 | 10 | 8~32mm |

| 100000 | 16 | 60000 | 5Tx4 | R6x2 | 120×120 | FF450x3 | FF400x2 | FF280x2 | 120×32 | 15 | 6.5~32mm |

| 200000 | 35 | 6000 | 10Tx4 | R6x2 | 150×150 | FF550x3 | FF450x2 | FF280x2 | 180×32 | 26 | 6~32mm |

| Specifications for reference only , could be adjust according to customer’s site area and requirement.Working day per year according to 300 days. | |||||||||||

Our Service

* Provide convenient combined overall solution including factory steel structure building, overhead cranes for steel mills, Continuous Casting and Rolling Production Line and related equipment.

* Provide turnkey project including design, manufacturing, transportation, installation, commissioning and testing service.

* Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout and other services.

* Provide guaranteed after-sale service.

Working principle of continuous rolling mill

The continuous rolling mill is an advanced process which can reduces the working load and improve the steel rolling speed. Its main feature is that the rolled steel metal is in a numbers of rolling mills at the same time, and are are rolled in the same direction, and finally form to a certain sectional shape such as steel rebar, wire rod, channel steel, section bar, flat bars, steel plates and other products.

images

About KORIGCRANES

KORIGCRANES ( HENAN WEIHUA KORIG CRANES CO., LTD) located in crane hometown of China (cover more than 2/3 crane market in China), who is a trusted professional industry crane manufacturer and leading exporter. Specialized in design, manufacturing, installation and service of Overhead crane, Gantry crane, Port crane, Electric hoist etc, we have passed ISO 9001:2000, ISO 14001:2004, OHSAS 18001:1999, GB/T 19001-2000, GB/T 28001-2001, CE, SGS, GOST, TUV, BV and so on.

Product Application

To meet the demands of the oversea market, we independent research and development European type overhead crane, gantry crane; electrolytic aluminum multi-purpose overhead crane, hydro-power station crane etc. European type crane with light dead weight, compact structure, lower energy consumption etc. Many main performance reach the industry advanced level.

KORIGCRANES Widely used in machinery, metallurgy, mining, electric power, railway, petroleum, chemical, logistics and other industries. Service for hundreds of large enterprises and national key projects such as China Datang Corporation, China Guodian Corporation, SPIC, Aluminum Corporation Of China(CHALCO), CNPC, Power China, China Coal, Three Gorges Group, China CRRC, Sinochem International, etc.

Our Market

Our cranes has been exported cranes to more than 110 countries for example Pakistan, Bangladesh, India, Vietnam, Thailand, Indonesia, Philippines, Malaysia、USA, Germany, France, Australia, Kenya, Ethiopia, Nigeria, Kazakhstan, Uzbekistan, Saudi Arabia、UAE、Bahrain、Brazil, Chile, Argentina, Peru etc and received good feedback from them. Very happy to be friends with each other come from all of the world and hope to establish long-terms good cooperation.

KORIGCRANES has steel pre-treatment production lines, automatic welding production lines, machining centers, assembly workshops, electrical workshops, and anti-corrosion workshops. Can independently complete the whole process of crane production.

Q. What’s the information should I provide when inquiry?

More details or drawings, better.

A: Lift capacity B: span C: lift height D: power source; other specials you give us will be more appreciated.

Q. How many operating methods for my selection?

Standard operating methods:

A: remote control with push buttons

B: cabin (space capsule seat) control with joystick. Choose any type as you like.

Q. Can this type work in hazardous environment?

A:Sure! We can customize for you, acid proof or explosion proof, no problem for that.

Q. Can you provide the serious lifting tools?

A:Sure, we can provide any lift tools such as lift sling belt, lift clamp, grab, magnet or other specials as your requirement!

Q. How can we install the crane?

A:Our senior engineer can be your side to do the installation guide service and training. Moreover, our best sales can visit your country.