Products

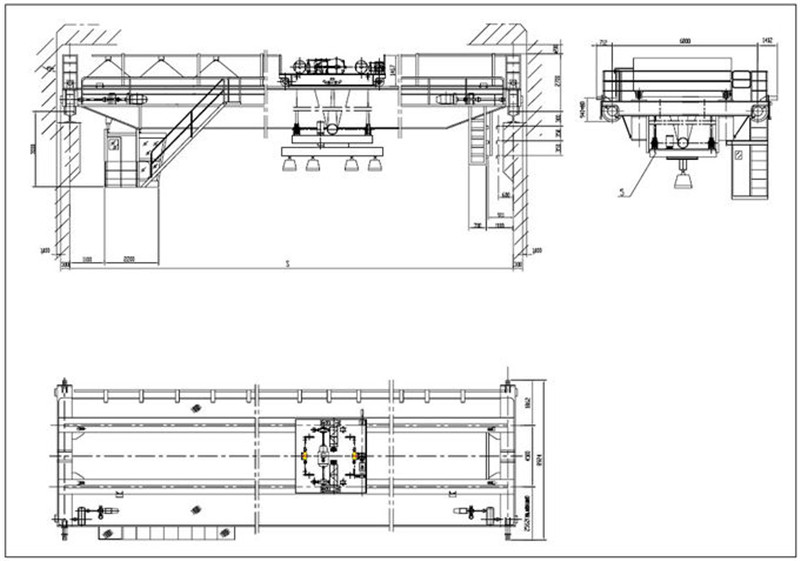

Double girder overhead crane with haning beam (paralleling with the beam)

Features

1. It is used for lifting 5t~50t stuff;

2. It has beautiful box-typed welded main girders. Computer-optimized design for main girders with good performance and lightweight;

3. Compact structure, lightweight and high lifting height;

4. The Max. span reaches 32 meters;

5. It's widely used in workshops, metallurgy, warehouses and assembly shops etc.

Technical parameters:

|

Lifting Capacity(t) |

Span (m) |

lifting height (m) |

working duty |

lifting speed (m/min) |

crane traveling speed (m/min) |

trolley traveling speed (m/min) |

total power |

|

15 |

22.5~31.5 |

16 |

A6 |

13.2 |

36.7 |

101.4 |

63 |

|

A7 |

15.8 |

36.6 |

103.9 |

79.5 |

|||

|

20 |

16 |

A6 |

12.6 |

36.2 |

89 |

71 |

|

|

15 |

A7 |

15.8 |

42.8 |

103.9 |

94.5 |

||

|

32 |

15 |

A6 |

12.5 |

37 |

87.3 |

111.3 |

|

|

16 |

A7 |

15.1 |

43.3 |

104.3 |

135.5 |

||

|

40 |

16 |

A6 |

11.7 |

37.5 |

87.3 |

128.5 |

|

|

A7 |

15.3 |

43.2 |

113.9 |

173 |

Mechanism

1. box-type shaped by wielding;

2. High-quality carbon steel Q235B and Q345B;

3. the girder connected by high strength screws;

4. Welding seams are tested by X-ray and ultrasound;

5. Forged wheels;

6. Compact structure, small volume and lightweight trolley;

7. The lifting mechanism is open type winch trolley;

8. Compact reducer motor drive, step-less control, hardened gears and safety disc brake;

9. Good operation performance, step-less speed regulating and running smoothly;

10. Main girders Shot blasting sa2.5 after welding to release internal stresses;

11. Painting high-quality epoxy zinc-rich primer, and the thickness of oil film is 140μm;

Electric System:

1. Power supply through step less slide lines;

2. Lifting mechanisms and traveling mechanisms are mutually independent and could travel at the same time;

3. Control panel protection degree is IP54;

4. Reasonable components installation, convenient for check and maintenance;

5. Electric cable is suspended in cable saddle, stationary cable trolley which slides on a galvanized C-type steel;

Safety Protection Devices:

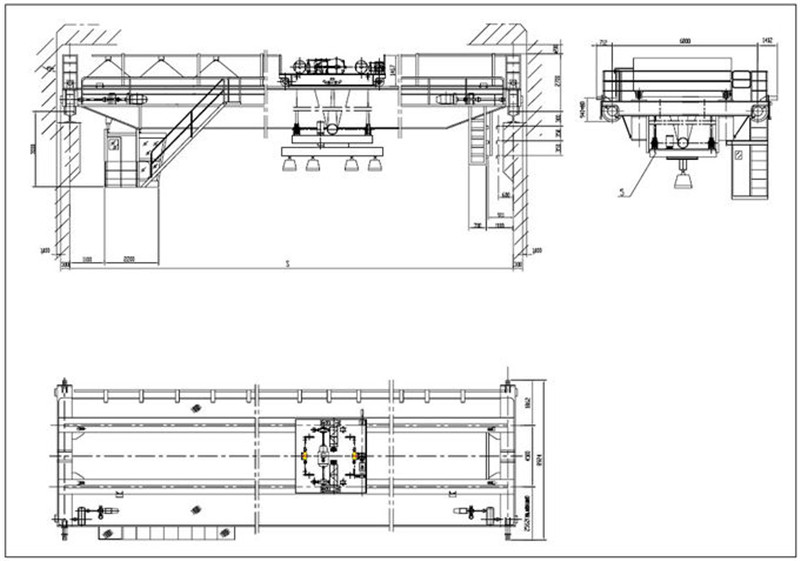

A6 Working Class QL Type Double Girder Magnet Crane with Electromagnetic Hanging Beam

The product description:

The crane has slewing carrier-beam, is applicable to the fixed span at indoor outdoors of steel mill, shipyard, port, yard and storage, etc.

It is used for loading, unloading and carrying steel plate, profile steel, and spool, etc. It is especially applicable to lift material of different specifications and which needs Horizontal rotation.

The carrier-beam is cross structure, which is reliable and has good safety features and has a certain function of preventing swinging, The lower part of the carrier-beam can bring special lifting appliances, such as magnetic chuck and tongs, etc.

Features:

1. It is used for lifting 5t~50t stuff;

2. It has beautiful box-typed welded main girders. Computer-optimized design for main girders with good performance and lightweight;

3. Compact structure, lightweight and high lifting height;

4. The Max. span reaches 32 meters;

5. It's widely used in workshops, metallurgy, warehouses and assembly shops etc.

Mechanism

1. box-type shaped by wielding;

2. High-quality carbon steel Q235B and Q345B;

3. the girder connected by high strength screws;

4. Welding seams are tested by X-ray and ultrasound;

5. Forged wheels;

6. Compact structure, small volume and lightweight trolley;

7. The lifting mechanism is open type winch trolley;

8. Compact reducer motor drive, step-less control, hardened gears and safety disc brake;

9. Good operation performance, step-less speed regulating and running smoothly;

10. Main girders Shot blasting sa2.5 after welding to release internal stresses;

11. Painting high-quality epoxy zinc-rich primer, and the thickness of oil film is 140μm;

Electric System

1. Power supply through step less slide lines;

2. Lifting mechanisms and traveling mechanisms are mutually independent and could travel at the same time;

3. Control panel protection degree is IP54;

4. Reasonable components installation, convenient for check and maintenance;

5. Electric cable is suspended in cable saddle, stationary cable trolley which slides on a galvanized C-type steel;

Safety Protection Devices:

Overload limiter, limit switch (lifting and traveling), interlocking protection devices, buffer, track sweep plate, shield, bus bar protection board, anti-collision device, main disconnecting switch, emergency stop system and motor overload protection.

| Lifting Capacity(t) | Span (m) | lifting height (m) | working duty | lifting speed (m/min) | crane traveling speed (m/min) | trolley traveling speed (m/min) | total power |

| 15 | 22.5~31.5 | 16 | A6 | 13.2 | 36.7 | 101.4 | 63 |

| A7 | 15.8 | 36.6 | 103.9 | 79.5 | |||

| 20 | 16 | A6 | 12.6 | 36.2 | 89 | 71 | |

| 15 | A7 | 15.8 | 42.8 | 103.9 | 94.5 | ||

| 32 | 15 | A6 | 12.5 | 37 | 87.3 | 111.3 | |

| 16 | A7 | 15.1 | 43.3 | 104.3 | 135.5 | ||

| 40 | 16 | A6 | 11.7 | 37.5 | 87.3 | 128.5 | |

| A7 | 15.3 | 43.2 | 113.9 | 173 |

About KORIGCRANES

KORIGCRANES ( HENAN WEIHUA KORIG CRANES CO., LTD) located in crane hometown of China (cover more than 2/3 crane market in China), who is a trusted professional industry crane manufacturer and leading exporter. Specialized in design, manufacturing, installation and service of Overhead crane, Gantry crane, Port crane, Electric hoist etc, we have passed ISO 9001:2000, ISO 14001:2004, OHSAS 18001:1999, GB/T 19001-2000, GB/T 28001-2001, CE, SGS, GOST, TUV, BV and so on.

Product Application

To meet the demands of the oversea market, we independent research and development European type overhead crane, gantry crane; electrolytic aluminum multi-purpose overhead crane, hydro-power station crane etc. European type crane with light dead weight, compact structure, lower energy consumption etc. Many main performance reach the industry advanced level.

KORIGCRANES Widely used in machinery, metallurgy, mining, electric power, railway, petroleum, chemical, logistics and other industries. Service for hundreds of large enterprises and national key projects such as China Datang Corporation, China Guodian Corporation, SPIC, Aluminum Corporation Of China(CHALCO), CNPC, Power China, China Coal, Three Gorges Group, China CRRC, Sinochem International, etc.

Our Market

Our cranes has been exported cranes to more than 110 countries for example Pakistan, Bangladesh, India, Vietnam, Thailand, Indonesia, Philippines, Malaysia、USA, Germany, France, Australia, Kenya, Ethiopia, Nigeria, Kazakhstan, Uzbekistan, Saudi Arabia、UAE、Bahrain、Brazil, Chile, Argentina, Peru etc and received good feedback from them. Very happy to be friends with each other come from all of the world and hope to establish long-terms good cooperation.

KORIGCRANES has steel pre-treatment production lines, automatic welding production lines, machining centers, assembly workshops, electrical workshops, and anti-corrosion workshops. Can independently complete the whole process of crane production.

Q. What’s the information should I provide when inquiry?

More details or drawings, better.

A: Lift capacity B: span C: lift height D: power source; other specials you give us will be more appreciated.

Q. How many operating methods for my selection?

Standard operating methods:

A: remote control with push buttons

B: cabin (space capsule seat) control with joystick. Choose any type as you like.

Q. Can this type work in hazardous environment?

A:Sure! We can customize for you, acid proof or explosion proof, no problem for that.

Q. Can you provide the serious lifting tools?

A:Sure, we can provide any lift tools such as lift sling belt, lift clamp, grab, magnet or other specials as your requirement!

Q. How can we install the crane?

A:Our senior engineer can be your side to do the installation guide service and training. Moreover, our best sales can visit your country.