Products

KBK Flexible crane

Suspensions

To prevent bending stresses and to minimise horizontal forces in the superstructure, KBK track sections are suspended so as to allow pendulation. Plastic shells in the upper and lower ball joints reduce maintenance, surge loading and noise to a minimum. The track height can be easily and precisely adjusted by means of the threaded suspension rods that connect the ball joint heads.

Track switches

Of compact, enclosed design, track switches are branching or converging components in the material flow. Options allow manual, electric or pneumatic switching for semi- or fully automatic control.

Drop sections

Drop sections are mainly used in closedcircuit tracks for picking up and depositing loads at predetermined positions. This eliminates the need for hoist units. When lowered in the drop section, the trolley is mechanically locked in place. Mechanical locks in the track stop other trolleys on either side of the drop section.

Turntables

Turntables make it possible to change direction in a minimum of space. Integrated mechanical locking devices prevent trolleys from leaving or entering the turntable section during the slewing operation. Turntables can be manually or electrically operated.

Features of KBK light rail system

1. Smooth Operation With Low Noise

KBK’s trolleys, consisting of durable bearings, travel with low noise and little friction, and do not generate iron scrap or leak oil. Universal joints of the clamps make crane operation smooth and agile.

2. Time-saving 3 Axis Movement

KBK’s 3 axis movement makes it a time-saving tool for a variety of factories, such as motor factories, clean room factories, logistic factories and factories requiring efficient movements of materials and components.

3. Simple Installation

KBK light rail system is designed to be connected with bolts and latches. With basic tools like hex wrenches, open-ended wrenches, and a level, one can easily complete the installation.

4. High Adaptability

KBK light rail system can adapt to a wide variety of locations, such as general factories, residence, and temporary constructions. It can be directly installed onto ceilings, RC beams, H-shaped beams, and flat or pitched roofs.

5. Great Flexibility

Modular design allows extendibility and relocatibility. KBK light rail system can easily meet the needs of workplaces by extending or shortening vertical and horizontal beams.

6. Excellent Adjustability

The excellent adjustability of KBK light rail system makes it perfect for workplaces with height limitation or unparalleled vertical beams (see illustration below). Compared with traditional overhead cranes, KBK light rail system is much more ideal for small and medium sized factories.

7. Easy Disassembly and Reassembly

KBK light rail system can be easily disassembled and reassembled, saving extra investment costs in case of relocations of factories or production lines.

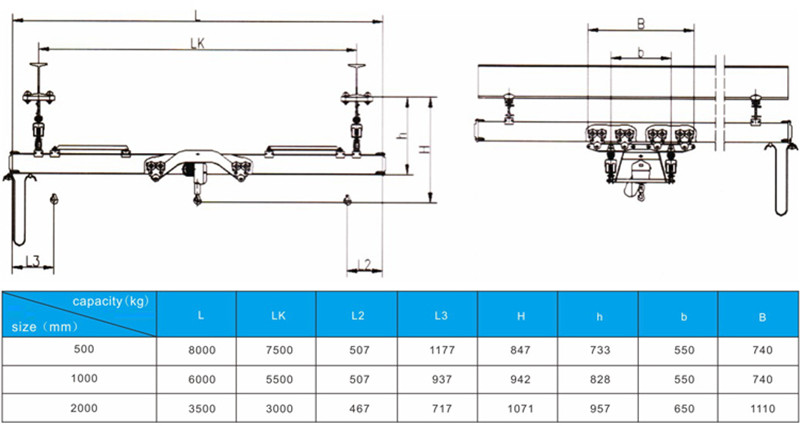

KBK light rail system assembly drawing

About KORIGCRANES

KORIGCRANES ( HENAN WEIHUA KORIG CRANES CO., LTD) located in crane hometown of China (cover more than 2/3 crane market in China), who is a trusted professional industry crane manufacturer and leading exporter. Specialized in design, manufacturing, installation and service of Overhead crane, Gantry crane, Port crane, Electric hoist etc, we have passed ISO 9001:2000, ISO 14001:2004, OHSAS 18001:1999, GB/T 19001-2000, GB/T 28001-2001, CE, SGS, GOST, TUV, BV and so on.

Product Application

To meet the demands of the oversea market, we independent research and development European type overhead crane, gantry crane; electrolytic aluminum multi-purpose overhead crane, hydro-power station crane etc. European type crane with light dead weight, compact structure, lower energy consumption etc. Many main performance reach the industry advanced level.

KORIGCRANES Widely used in machinery, metallurgy, mining, electric power, railway, petroleum, chemical, logistics and other industries. Service for hundreds of large enterprises and national key projects such as China Datang Corporation, China Guodian Corporation, SPIC, Aluminum Corporation Of China(CHALCO), CNPC, Power China, China Coal, Three Gorges Group, China CRRC, Sinochem International, etc.

Our Market

Our cranes has been exported cranes to more than 110 countries for example Pakistan, Bangladesh, India, Vietnam, Thailand, Indonesia, Philippines, Malaysia、USA, Germany, France, Australia, Kenya, Ethiopia, Nigeria, Kazakhstan, Uzbekistan, Saudi Arabia、UAE、Bahrain、Brazil, Chile, Argentina, Peru etc and received good feedback from them. Very happy to be friends with each other come from all of the world and hope to establish long-terms good cooperation.

KORIGCRANES has steel pre-treatment production lines, automatic welding production lines, machining centers, assembly workshops, electrical workshops, and anti-corrosion workshops. Can independently complete the whole process of crane production.

Q. What’s the information should I provide when inquiry?

More details or drawings, better.

A: Lift capacity B: span C: lift height D: power source; other specials you give us will be more appreciated.

Q. How many operating methods for my selection?

Standard operating methods:

A: remote control with push buttons

B: cabin (space capsule seat) control with joystick. Choose any type as you like.

Q. Can this type work in hazardous environment?

A:Sure! We can customize for you, acid proof or explosion proof, no problem for that.

Q. Can you provide the serious lifting tools?

A:Sure, we can provide any lift tools such as lift sling belt, lift clamp, grab, magnet or other specials as your requirement!

Q. How can we install the crane?

A:Our senior engineer can be your side to do the installation guide service and training. Moreover, our best sales can visit your country.