Products

Mobile type Scissor Lift

overview

The Mobile Scissor Working Platform is divided into 4, 6, 10, 12, 14, 16, and 18 meters according to the elevated height. The load capacity of the series products is 300/500 kg, and other loads need to be customized separately. Using high-strength manganese steel structure, four-wheel movement is convenient, the working table is wide, and the bearing capacity is high. It is suitable for installation, maintenance and cleaning of high-altitude equipment such as construction sites, workshops, warehouses, grain depots, stations, border crossings, airports, docks, gas stations, stadiums, elevated pipelines, etc. Plant maintenance, etc. This equipment can add assisted walking/five-wheel assisted walking function, which can be moved by a single person, and the operation is more convenient.

Self-propelled scissor-type aerial work platform: It can walk fast and slow at different heights, and can continuously complete up and down, forward, backward, steering and other work on a convenient operation platform in the air. Using high-quality structural steel, laser welding electronic manipulator single-sided welding double-sided forming process, imported hydraulic pump station from Italy or Anshan joint venture hydraulic pump station, aerospace cartridge valve technology, the platform is equipped with a level alarm, balance valve, automatic safety board, etc. Alarm device, the platform is safe, reliable and durable, the working height can reach 12 meters, the load is 300 kg, the fence can be extended horizontally, which greatly expands the operating range, one-year warranty, suitable for factory workshops, square lobby airports, parks and other high-altitude operation needs customer.

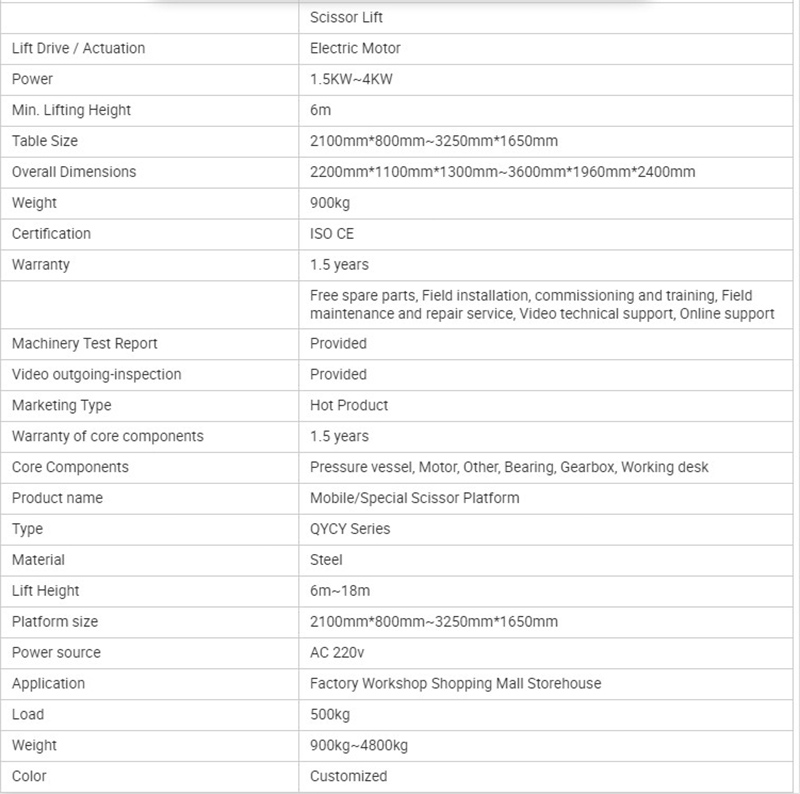

parameter

features

1. Quiet and convenient devices

This scissor lift takes storage battery as the power source, and makes low noise and no emission when working, so it can be used indoor occasions, such as workshops, warehouse, hotels, etc

2. Scissor structure

The scissor structure are made by advanced CNC machine, which make every lift parts extremely precise and can cut-max 20 mm thickness steel structure and error will be less than three-thousandths of a millimetre.

3. Flexible

The steering wheel can make a 90°turn in situ, can runin both high and low speeds, and can be used in small place.

4. Larger working space

The platform can extend on one side, which can enlarge the working space.

5. Easy understanding control box-on the platform.

Each control button has the instruction mark, the user can understand how it works and easy to operate.

6. Emergency stop value and charger hole, and the voltage can be made as your local supply.

7.Each lift will be fully tested before factory, we will assure every part works and make the video for the customer.

About KORIGCRANES

KORIGCRANES ( HENAN WEIHUA KORIG CRANES CO., LTD) located in crane hometown of China (cover more than 2/3 crane market in China), who is a trusted professional industry crane manufacturer and leading exporter. Specialized in design, manufacturing, installation and service of Overhead crane, Gantry crane, Port crane, Electric hoist etc, we have passed ISO 9001:2000, ISO 14001:2004, OHSAS 18001:1999, GB/T 19001-2000, GB/T 28001-2001, CE, SGS, GOST, TUV, BV and so on.

Product Application

To meet the demands of the oversea market, we independent research and development European type overhead crane, gantry crane; electrolytic aluminum multi-purpose overhead crane, hydro-power station crane etc. European type crane with light dead weight, compact structure, lower energy consumption etc. Many main performance reach the industry advanced level.

KORIGCRANES Widely used in machinery, metallurgy, mining, electric power, railway, petroleum, chemical, logistics and other industries. Service for hundreds of large enterprises and national key projects such as China Datang Corporation, China Guodian Corporation, SPIC, Aluminum Corporation Of China(CHALCO), CNPC, Power China, China Coal, Three Gorges Group, China CRRC, Sinochem International, etc.

Our Market

Our cranes has been exported cranes to more than 110 countries for example Pakistan, Bangladesh, India, Vietnam, Thailand, Indonesia, Philippines, Malaysia、USA, Germany, France, Australia, Kenya, Ethiopia, Nigeria, Kazakhstan, Uzbekistan, Saudi Arabia、UAE、Bahrain、Brazil, Chile, Argentina, Peru etc and received good feedback from them. Very happy to be friends with each other come from all of the world and hope to establish long-terms good cooperation.

KORIGCRANES has steel pre-treatment production lines, automatic welding production lines, machining centers, assembly workshops, electrical workshops, and anti-corrosion workshops. Can independently complete the whole process of crane production.

Q. What’s the information should I provide when inquiry?

More details or drawings, better.

A: Lift capacity B: span C: lift height D: power source; other specials you give us will be more appreciated.

Q. How many operating methods for my selection?

Standard operating methods:

A: remote control with push buttons

B: cabin (space capsule seat) control with joystick. Choose any type as you like.

Q. Can this type work in hazardous environment?

A:Sure! We can customize for you, acid proof or explosion proof, no problem for that.

Q. Can you provide the serious lifting tools?

A:Sure, we can provide any lift tools such as lift sling belt, lift clamp, grab, magnet or other specials as your requirement!

Q. How can we install the crane?

A:Our senior engineer can be your side to do the installation guide service and training. Moreover, our best sales can visit your country.