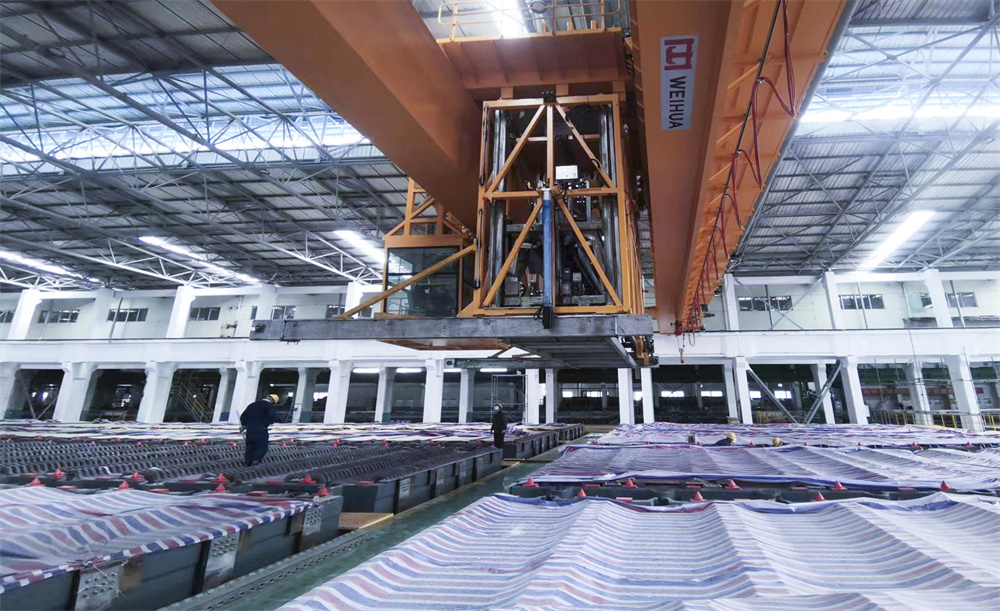

The special crane for electrolytic copper developed by KORIG CRANES through independent innovation was successfully delivered to a project in Guangdong.

As the biggest highlight of the product, the special copper electrolytic sling is used for the automatic discharge and slotting operation of cathode (starting plate) and anode plate. It has many functions, high degree of automation, reliable insulation, stable performance and other advantages.

The spreaders are independently developed products of KORIG CRANES. The main structure is made of high-quality stainless steel, with high strength and acid corrosion resistance, and the cost is greatly reduced while the quality is excellent. It is the only choice for users to reduce cost and increase efficiency. In addition, the spreader also has the following characteristics:

1. Specially designed platen function and shooting device to ensure that the initial cathode plate can be smoothly slotted;

2, meet the cathode plate and anode plate lifting alone and the whole joint lifting, high efficiency;

3, the combination of pre-positioning and fine positioning, positioning accuracy ±2mm;

4, flat push type liquid plate open and close smoothly, to ensure that the electrolyte does not spill.

The suspender is a product independently developed by KORIG CRANES. The main structure is made of high-quality stainless steel with high strength and acid corrosion resistance. The cost is greatly reduced while the quality is excellent.

1. The machine has three operation modes: automatic, semi-automatic and manual;

2, the vehicle adopts frequency conversion and PLC precise control, high precision positioning;

3. The driver’s cab can synchronously monitor the insulation status of spreader, motor, transformer and other devices, and give an alarm when leakage occurs;

4, four motor structure to meet the function of deviation correction, stability and reliability greatly improved.

Post time: May-03-2023